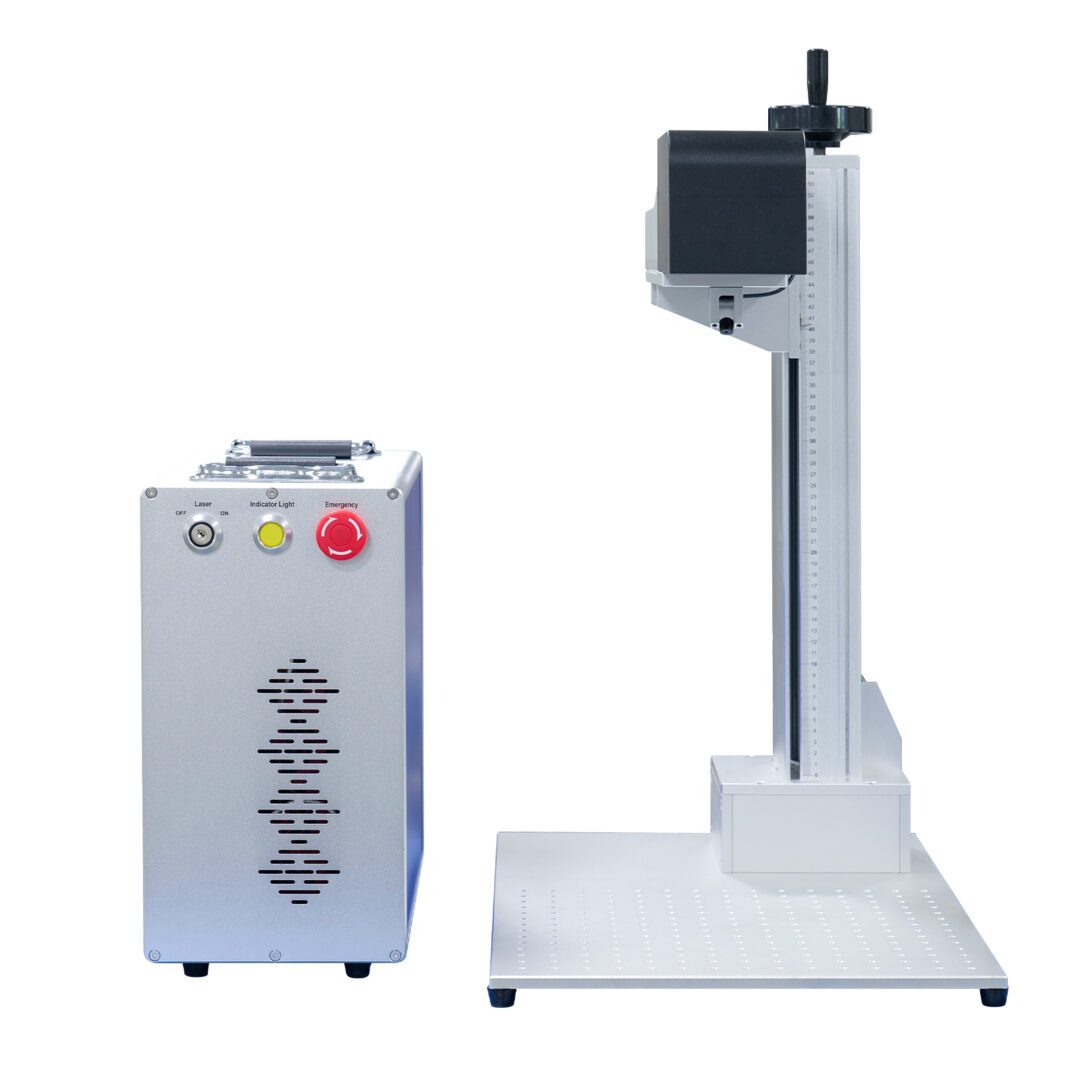

60W 80W 100W 3D Dynamic Fiber Laser Engraver 3D MOPA Fiber Laser Marking Machine

$17,199.00

YDFLP-M7-M-R JPT MOPA M7, 200*200mm Engraving Field(FEELTEK 3D Galvo),

Lenmark Software. Wavelength: 1064nm; Different Steps, Cone Surface, Slope

Surface Marking

Description

Product Parameters: Laser Source: 60W/80W/100W JPT MOPA M7 Marking Area:

100*100mm(4*4in)/200*200mm(8*8in) optional Repetition Rate: 1-4000kHz Pulse

Duration: 2-500ns Output Power Adjustment Range: 10%-100% Marking Speed: ≤

7m/s(275.6in/s) Engraving Depth:

≤1.2mm(0.008in)/1.5mm(0.016in)/2.0mm(0.039in) Minimum Line Width:

0.01mm(0.0004in) Depends on the material Minimum Character: 0.2mm(0.0008in)

Electrical Requirements:110V-240V/50Hz-60Hz(According to local electricity

supply) Power Consumption: 1200W/1300W/1500W Marking Interface: USB

connection, Compatible with Windows XP/Vista/7/8/10 Communication Mode for

Automation: TCP/IP, IO, RS232 Marking Content: barcodes, serial numbers,

text, vector and logos Red Dot Pointer: Since the laser beam is incisible,

the red dot pointer allows you to have a visual reference for locating

where the laser will fire. Features and Advantages: Adopted advanced optical design scheme, it is characterized by small light

loss, small volume, high positioning accuracy, fast marking speed and

strong anti-interference ability, etc. It is suitable for laser fine

processing of various large surface, complex surface and deep carving. High

speed system, meets above 3000mm/s precision hatch speed. Maximum marking

height up to 80mm@200*200mm Maximum scan field up to 200*200mm, meets large

scan field engraving requirements. (300*300mm/400*400mm optional) precisely

control the focal length position of laser marking machine, automatically

adjust Z-axis for 3D deep marking process, keep the spot size to minimum,

ensure the uniform graphic effect after marking on the object. Adopted

lenmark 3D software system(MM3D Optional) to support various file formats,

vector, bitmap and text bar code import, which is easy to learn and

operate. Built-in concave and convex circular tube, concave and convex

sphere, slope, cone, polygon and other basic models, the operator can

easily and rapidly set the marking. 3D models can be imported; 2D graphics

can be directly cladded or projected on built-in curve surface. The whole

system adopted the optimization designing of electromagnetic compatibility,

with high signal-to-noise ratio and strong anti-interference ability.

Precision optical adjustment. The optical adjuster could solve the common

difficulty of adjustment from QCS interface optical offset. Once adjusted,

accurate to the central point. Compact design, easy for integration.

Integrated structure, dust prevention, and shielding design without space

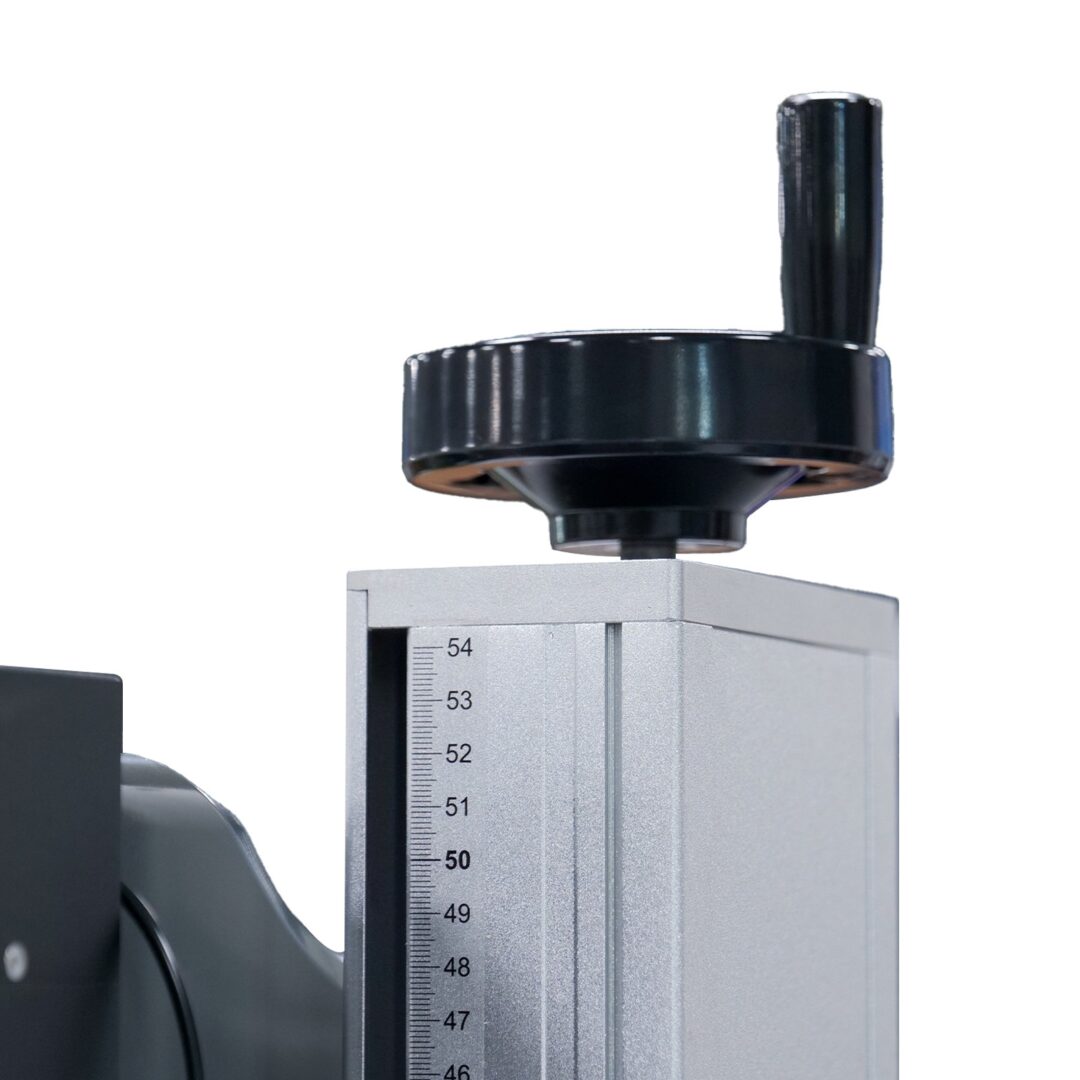

limiation, very easy to integrate. Easy to switch work field. The

adjustment knob is used to switch between different work fields without

replacing any parts. 3D control, multiple complicated surface

processing. Different steps, cylinder surface, cone surface, slope surface,

etc. Duble driving Z axis dynamic focus module design, reponse frequency

100Hz@±10° The special quick-inserting optical bench can achieve light path

adjustment and installation in fast way. The dynamic focus control

technology, breaks the limitation of traditional marking, and can do

distortion marking in the large-scale surface, 3D surface, steps, cone

surface, slope surface, and other objects. Engraving. The dynamic axis

collaborates with the XY axis scannhead, can easily layered relief, deep

carving and texture etching. High precision. With the increasing processing

layer, the dynamic focus axis jointly adjusts the focal length and spot in

real-time to encuse that the focus spot controllable during te whole

processing process, which can adcieve higher accuracy compared with

traditional scanhead. High Efficiency. The dynamic axis is fully

coordinated with the XY axis, and the hierarchical focus compensation is

completed with miroseconds with a more efficient job. Multiple applicable

environments. Without the extra moving platform, the dynamic focus system

can achieve accurate 3D marking, engraving and other laser applications.

Suitable material: brass, carbon steel, mold steel, stainless steel, SIC

etc.